- All materials in contact with product are of 316L stainless steel and the seals are made of food grade materials.

- With weighing filling mode, we can meet the filling requirements for Corn Oils of 700ml, 900ml, 1.5L, 2.5L, 5L, 10L and other volumes.

- The screw arbor or thumb wheel are used for bottle transmission and separation. The bottle bottom is hold all the way to reduce the replacement of changeover parts. The changeover parts are of quick-change structure, which can improve efficiency by reducing the time for replacement.

- We pay attention to hygienic design and introduce various protection methods to offer a contamination-free filling environment.

Description

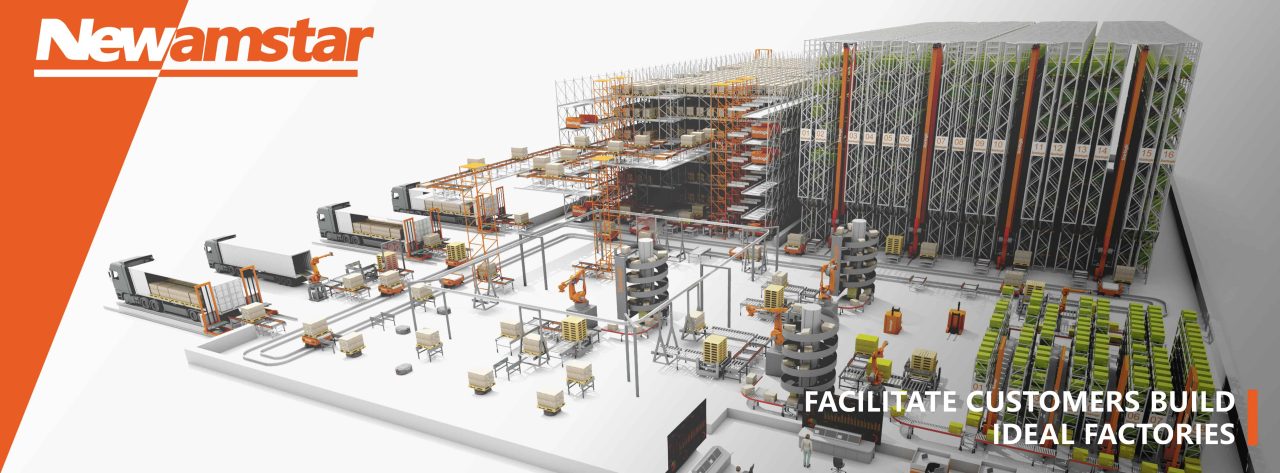

Over the years, Newamstar has made continuous breakthroughs and innovations in the field of Corn Oil packaging technology. On the one hand, it has successively launched packaging solutions for the production line of high-speed blowing-filling-capping combiblock for 10L large bottles and 500ml small bottles. On the other hand, combined with the whole life cycle of the production line, it has built an intelligent production line management system and product safety traceability system based on the edible oil industry to help customers realize operation monitoring, performance analysis, energy management, maintenance analysis, production reports, production tracking and other functions which can make production management more relaxed, convenient and intelligent. Discover how our tailored solutions can foster sustainable growth and profitability from end-to-end.

- Applicable Products: Corn Oil

- Suitable Container: Plastic containers (PET and HDPE), glass containers or metal containers

- Filling Modes: Mechanical valve filling or electronic valve filling

- Production Capacity: 5,000 bottles/hour – 36,000 bottles/hour

1. Whole-Plant Project

With high-quality equipment, perfect service, and strong turn-key service capabilities, Newamstar helps customers achieve a high-efficiency operation of equipment and technical innovation and upgrade to join hands with customers for a win-win situation.

2.After-Sales Support

With the expansion of the global market, Newamstar will, relying on six domestic and overseas service centers, provide technical support and after-sales services to customers all over the world to protect the development of customers’ business.

3.Spare Parts

Taking full consideration of customers’ actual situation and needs, Newamstar will ensure the stable operation of their equipment according to the operation of the customers’ factory and provide spare parts support for them in time.

Greater customer benefits

Running production tasks shall require significantly less time and effort, allowing customers to focus entirely on their core business.

Greater flexibility

Customers shall be in a position to increase their adaptability and react flexibly to changes in the market or in their business models.

Greater profitability

System performance shall be adapted to the required availability, thus increasing profitability by minimizing staffing, reducing wear, and decreasing energy consumption.

We can help you capitalize on today’s innovative technologies to become more agile, respond effectively to change, improving the entire line of production efficiency, reducing investment costs, energy consumption and maintenance costs, and position your business for a successful future.

From the filling method and output, through to the level of hygiene: Newamstar specialists will be only too pleased to provide you with advice on the best system to use in your bottling line.

WhatsApp: +86 18521300509

E-Mail: e@newamstar.com

Web: http://en.newamstar.com/

Linkedin: https://www.linkedin.com/company/newamstarchina/

Facebook: https://www.facebook.com/newamstarchina/